Lamination could be glossy and matte. It is the process of gluing a layer of protective coating (often some type of plastic) onto the paper surface.

During paper box and paper bag printing process, lamination is usually used for improving its sturdiness and water resistance. What’s more, lamination could help to improve the tactile feel of the printed surface and contribute to a smooth finish.

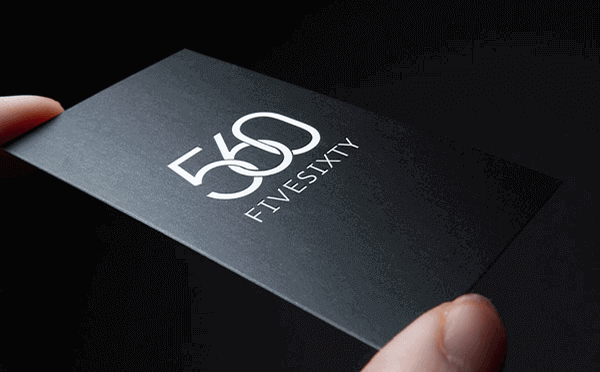

Difference between high glossy and matte lamination:

Glossy Lamination

When a high glossy laminate is applied to the printed surface, graphics and texts will have more contrast, better sharpness and clear crystal shiny effect to attract customers’ attention.

Matt Lamination

Matte lamination prints appear to have more subdued. Its luxurious and elegant surface on packaging products, such as gift box, cosmetic box and paper bag usually help to make a difference on the markets.

Generally, lamination is required if printed paper is with general art paper, as it could help to preserve the color on box and bag from fade away and also for sturdiness and waterproof.