Paperboard boxes were made by cutting, folding and gluing with much hand work but, in that year, Robert Gair in America took out a patent for the mechanized process of cutting and creasing board which is essentially the same as that used today. Initially, converted printing machines were used; now, cutting and creasing presses are purpose-designed with outputs to match the present- day demands for precision and productivity.

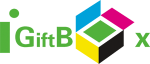

Application: Brand promotion, gift Packaging, Holiday gift, food packaging etc. Custom Branding Suggestion: Branding in a great selection of colors, including metallics.

| Optional Features | |

| Size | According to customers` specific requirements. |

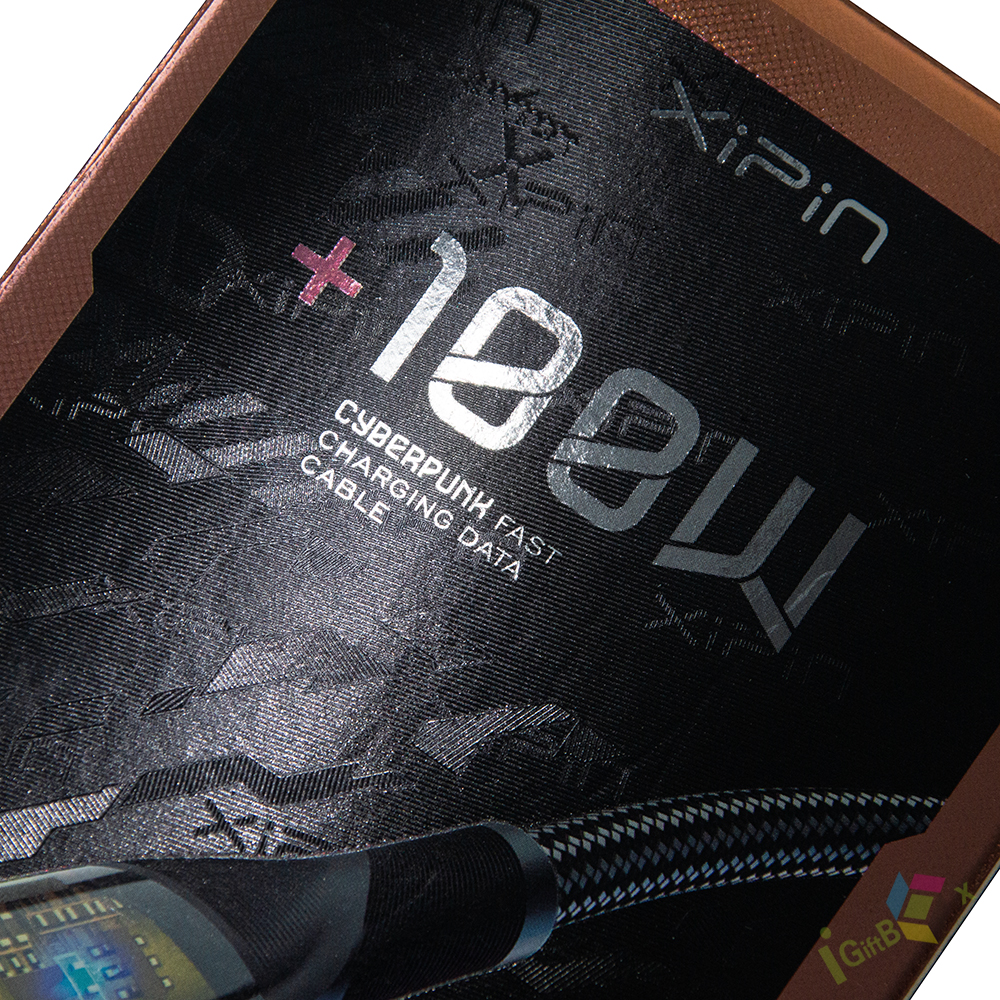

| Shape and Style | Rectangle, square, circular, oval, especialShape: modern design, classy style and archaize style |

| Material | 600g-1600g paper cardboard128g-250g art paper; 100-130g fancy paperCorrugated B-flute, C-flute, E-flute, F-flute paper |

| Printing | CMYK 4 color offset printing, screen printing, Pantone color, UV printing. |

| Finishing | 1) Glossy/Matte lamination2) Complete or Spot UV3) Embossing and Debossing4) Gold or silver foil stamping5) Varnishing |

| Accessories | Magnet, ribbon, EVA form , plastic tray, sponge, PVC/PET/PP window |

| Brand | OEM and ODM are available |

| Packing | PP Bag, Standard Exporting Cartons |

| Industry | Gift, food, wine, cosmetics, perfume, garments, jewelry etc. |