The folding box is familiar as a retail pack in the distribution of food stuffs, confectionery, toiletry and cosmetics, tobacco products, light engineering goods, and toys and games. Prior to 1879, paperboard boxes were made by cutting, folding and gluing with much hand work but, in that year, Robert Gair in America took out a patent for the mechanized process of cutting and creasing board which is essentially the same as that used today. Initially, converted printing machines were used; now, cutting and creasing presses are purpose-designed with outputs to match the present- day demands for precision and productivity.

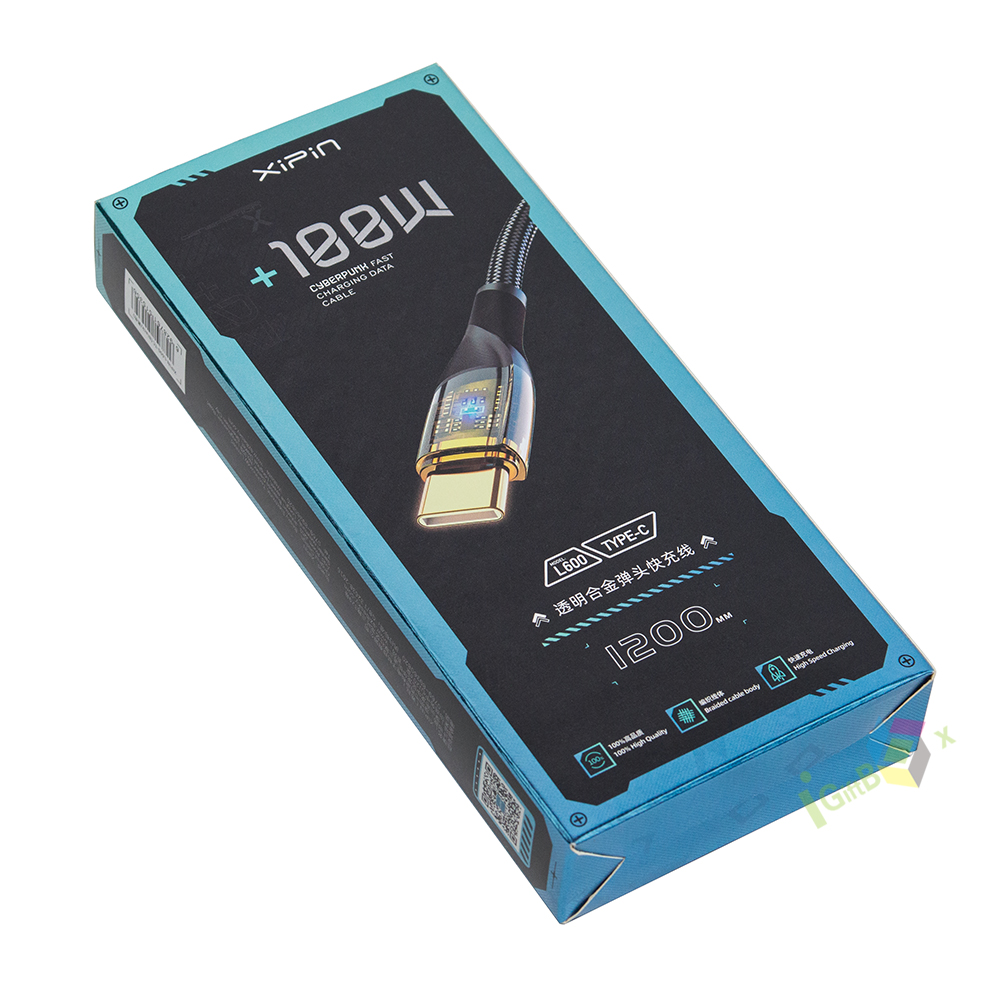

Application: Brand promotion, gift Packaging, Holiday gift, food packaging etc. Custom Branding Suggestion: Branding in a great selection of colors, including metallics.

| Optional Features | |

| Size | According to customers` specific requirements. |

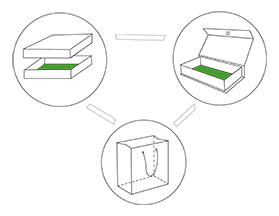

| Shape and Style | Rectangle, square, circular, oval, especialShape: modern design, classy style and archaize style |

| Material | 600g-1600g paper cardboard128g-250g art paper; 100-130g fancy paperCorrugated B-flute, C-flute, E-flute, F-flute paper |

| Printing | CMYK 4 color offset printing, screen printing, Pantone color, UV printing. |

| Finishing | 1) Glossy/Matte lamination2) Complete or Spot UV3) Embossing and Debossing4) Gold or silver foil stamping5) Varnishing |

| Accessories | Magnet, ribbon, EVA form , plastic tray, sponge, PVC/PET/PP window |

| Brand | OEM and ODM are available |

| Packing | PP Bag, Standard Exporting Cartons |

| Industry | Gift, food, wine, cosmetics, perfume, garments, jewelry etc. |